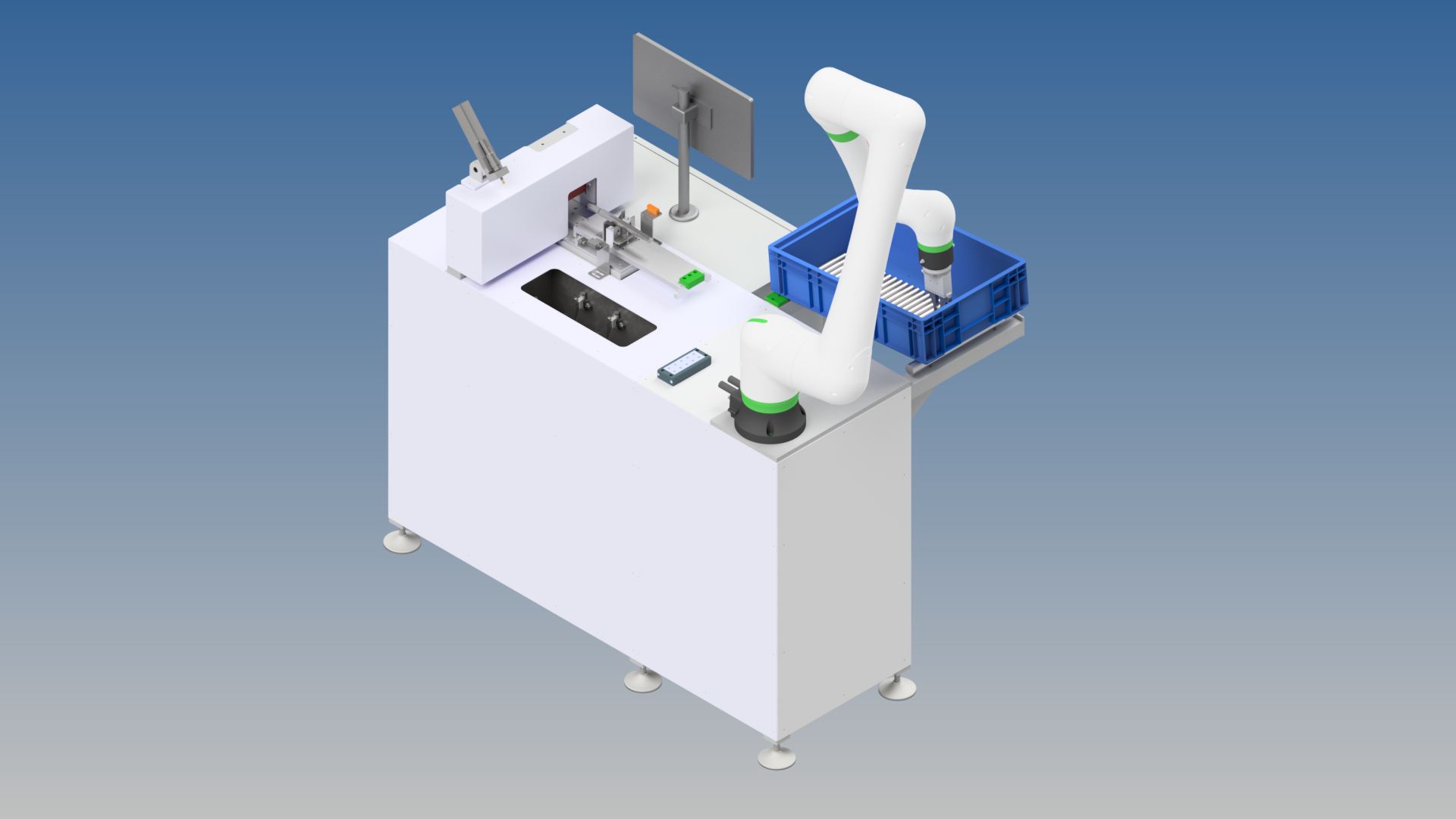

Automated quality control

Precision & reliability in industrial quality control

In the manufacturing sector, quality is an essential factor to guarantee high performance and reduce waste. Automation in quality control allows for rapid, repeatable and human error-free measurements, ensuring increasingly higher standards.

Our automated quality control solutions integrate advanced technologies for the micrometric measurement of components, ensuring precise analysis of dimensional tolerances. The use of robotic systems allows for continuous operation, with high repeatability and traceability of data, optimizing the production process and improving the reliability of the finished product.

Main features of the island

High precision micrometric measurement

It ensures accurate control of diameters and tolerances with a precision in the order of microns depending on the verification device applied.

Quality Control Automation

It reduces the need for human intervention, minimizing the risk of errors and ensuring process repeatability.

Communication with the machine tool

The island is able to interface with the processing machinery, automatically sending corrections to the tolerances to ensure the conformity of the produced pieces.

Adaptability to different production contexts

The island can operate both in process, integrated directly into the production line for continuous quality control, and stand-alone, as an independent station for sample or end-of-line checks.

Our automated measuring cell guarantees extremely accurate quality control, thanks to the combination of advanced technologies and robotic automation. The system performs micrometric measurements, records data in real time and communicates directly with the machine tool to automatically correct processing tolerances.

Operating both in process and stand-alone, the cell ensures repeatability, reliability and optimization of the production process, reducing waste and improving the quality of the finished product.